Design tips,

DIY Advice

Polished Porcelain Handout

07.01.20

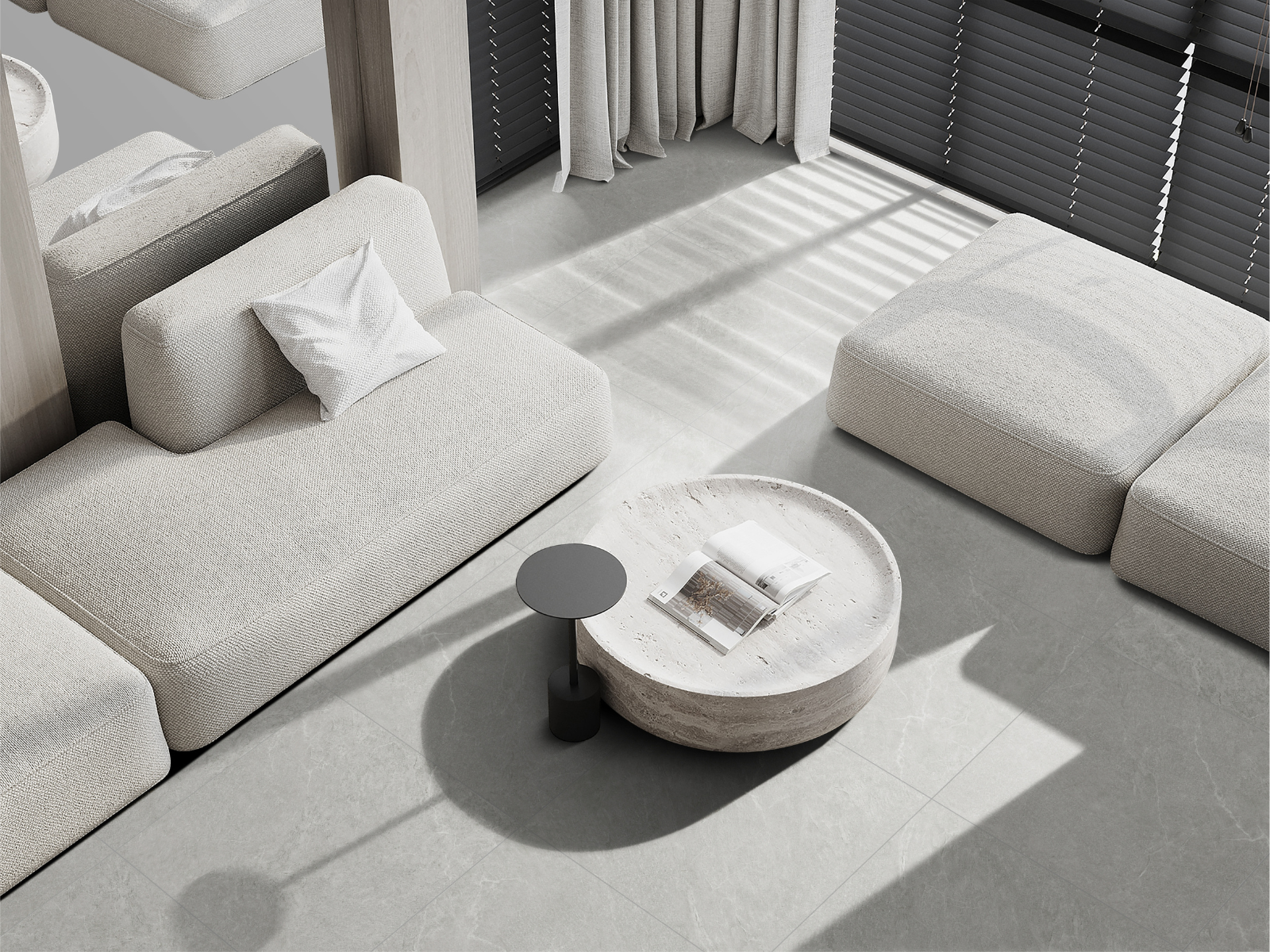

Polished Porcelain Tiles, with their light reflective qualities, have long been chosen for their upmarket appeal. From shoppingcentres to hotels, polished porcelain has a streamlined, classic appeal that is widely desired.

There are a few important things which are specific to Polished Porcelain Tiles that you should be aware of. Unlike standard glazed ceramics, polished porcelain is an unglazed tile. Similar to natural stone, the reflective qualities are achieved through polishing the surface of the tile. During this polishing process, the small particles that constitute the tile are broken and tiny "micropores" are created. This raises 2 unique issues -

TILES MAY REQUIRE SEALING

While the "micropores" on the tile surface may be invisible to the naked eye, they may mean the tile is susceptible to staining. To avoid this problem tiles may need to be sealed. Sealing will assist protect the tile against staining for a certain period of time (a bit like scotch guarding your furniture or shoes). Tiles can be factory sealed or sealed on site - both systems are effective and will assist protect the tiles for as long as the life of the sealant. You may encounter the terms "Nano sealing" or "Nano technology" - this is a relatively new type of factory coating/sealant coming from China.

You may also encounter the term "High Density" - these products are more dense and have undergone finer polishing. In some cases suppliers will claim these products are "Maintenance Free" because the tiny holes and crevasses are so small that they do not need any sealant to keep the tile clean. Staining elements can be removed with a porcelain cleaner (obviously no stain should be left on any finish for extended periods without attempting treatment). As the maintenance-free characteristic of the tile is due to the quality of the manufacturing process, it will remain unchanged and maintenance-free for as long as the tile is in use. Your sales assistant will be able to advise whether sealing is recommended for your polished porcelain tile. If sealing is recommended for your polished porcelain, it is important to first remove any residue from the surface of the tile or else this will become "sealed in" and difficult to remove. Most polished porcelain tiles are manufactured with a protective film of plastic or wax over the polished surface. The film protects the surface from scratching and staining during transportation, laying and grouting. Wax is generally the most accepted application as it can be applied quickly during manufacture and has a better resistance to scratching than a plastic sheath. However, the wax can sometimes be difficult to remove. Wax is always best removed after the final grouting. As with most waxes, heat applied to the surface will loosen the wax and allow easier removal. Heat can be applied through either a heat gun (commonly used to remove paint etc), very hot water or steam. Care should be taken not to overheat the surface and to ensure heat is applied safely. Liquefied wax can then be removed with a Porcelain Cleaner. Once completely cleaned, the surface should be dried and sealed to help protect from any possible staining.

OPTICAL HAZING IS A NATURAL PHENOMENON

"Optical Hazing" presents as a smoky, hazy, smudgy type of finish in the surface of polished porcelain tiles. It will only be visible when a direct light source reflects at a certain angle across the surface of the tile. Optical Hazing is caused by light reflecting off the surface. Reflection off a smooth surface such as a mirror is known as " specular reflection". Reflection off a rough surface such as ceramic tiles is known as "diffuse reflection". Many consumers have

Amber recommends products be installed by a professional tradesperson. These instructions are to be used only as guides. Amber does not accept responsibility for any incorrect installation results or improper preparation. For individual advice speak to your local Amber store.